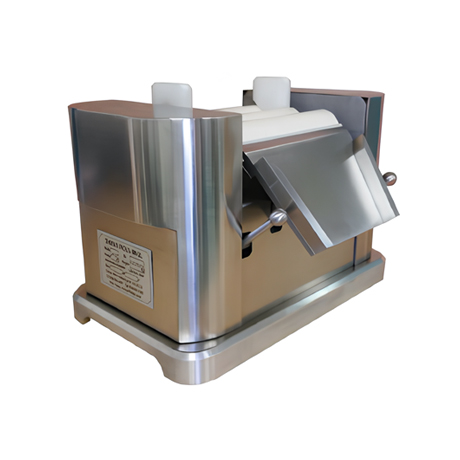

T50 Ointment Mill

Feature

● Roller Size : (직경)50mm x (길이)178mm 의 폭넓은 알루미나 롤러

● Higher Output

● Super Fine Blending Results

– Precise 99.5% Alumina rollers

– Ground to 5um concentricity

– 0.5um surface finish

Gritty 한 연고, 화장품등을 즉각적으로 uniform, smooth하게 만들어 줍니다.

● Ointment외 다양한 어플리케이션 적용가능

● 화장품 제약에 널리 사용

Application

1) Anti-Aging, Skin Care, Cosmeceutical Compounding

2) Hormone Replacement Therapy Compounding

3) Pain Management Compounding

4) Diabetic Compounding

● Roller Speed Ratio : 1 : 1.8 : 3.3(fixed)

● Roller Material : Alumina

● Innovative Gap Adjustment Mechanism

– 빠르고정확한 갭사이즈 컨트롤

– 조정하기편리한 머케니즘

– 정확한 롤러 얼라인먼트

● Longer Rollers and Faster Speed for Higher Output

– 경쟁사보다 길어진 롤러

● Continuous Speed Control

Specifications

| Parameter | T50 Ointment Mill | |

|---|---|---|

| Roller Material | Alumina | |

| Diameter of Roller | 2.0” (50mm) | |

| Length of Roller | 7"(178mm) | |

| Roller Speed Ratio (Fixed) | 1 : 1.8 : 3.3 | |

| Speed of Roller RPM | Slow Roller | 0~219 |

| Mid Roller | 0~394 | |

| Fast Roller | 0~723 | |

| Motor Power | 120 W | |

| Weight | 45 lbs (21kg) | |

| Throughput(생산성) | up to 15 kg/h(one pass) | |

| Dimensions | 380mm x 255mm x 240mm | |

| Input Voltage | 110V, 60Hz or 220V,60Hz | |

쓰리롤 밀 작동 방법

쓰리롤 밀은 수평으로 놓여진 세개의 롤이 서로 반대방향으로 각각 다른 스피드로 회전하면서 생기는

전단력을 이용한 기기이다.

주로 고점성 물질을 mix, refine, disperse, or homogenize 처리하기 위함이다.

대부분 electronic thick film inks, high performance ceramics, cosmetics, plastisols, carbon/graphite,

paints, printing inks, pharmaceuticals, chemicals, glass coatings, dental composites, pigment, coatings,

adhesives, sealants, and foods 부분에서 광범위하게 사용된다

위 그림에서 보듯이, 물질은 feeder roll과 center roll 사이에 붓고, 롤과 롤사이의 좁은간격과 매우높은

High shear force로 바인더 속의 pigment particle을 분산한다.

Structure of the T50 Ointment mill

A. Front, center and rear rollers

A. Front, center and rear rollers

B. Apron plate

C. Rod for dischargeable apron plate

D. Fine adjustment socket

E. Quick adjustment knobs for roller gaps

F. Speed adjustment knob

G. Power Switch

H. Fastening screw for hopper

I. End plate

J. Hopper

Feeding Parts

- 양측의 End Plate로 거리를 조정하면서 셋팅합니다.

Hopper

- 샘플의 양이 많을 경우에 Hopper를 장착합니다.

- 간편하고 쉬운 탈부착

립스틱의 제조

Lipsticks 의 일반적인 처리 단계

(1) pigment milling,

(2) combination of pigment phase into the base,

(3) molding, and

(4) flaming.

밀링은 particle사이즈를 줄이기도 하지만 그보다 뭉쳐진 안료를 풀어내는 것이라 할 수있습니다

쓰리롤 밀에 의해 처리된 paste의 결과는 보통 20micron 정도가 됩니다

[참고사항]

Combination of pigment phase into the base is a simple procedure. The wax and oil phase are usually melted in a steam-jacketed kettle equipped with a single propeller agitator. Following this, the milled pigment phase is added.

Molding is by use of vertical split molds. Most lipstick formulations mold well between 75 and 85 C.

Pre-heating the mold be around 35 C avoids the formation of “cold marks” on the stick,

and holding the mold at a light angle to the vertical is a technique often used to avoid air entrapment.

Rapid cooling after the mass is poured into the mold of important since it leads to a smaller,

more uniform crystalline, structure, which, in turn, leads to better stability and gloss. Once cooled,

the molds can be spit open and the sticks subjected on to the trays or some other suitable storage

container until they are ready for flaming.

Flaming is a procedure for passing the molded stick through the flame of a gas burner, or series or

burners, to increase the surface gloss. The flames are adjusted to a level just hot enough to just melt

the surface of the stick.